Streamlining Efficiency and Compliance: A Success Story with Applus+

In the ever-evolving landscape of asset management and compliance, the need for efficient,...

In the ever-evolving landscape of asset management and compliance, the need for efficient,...

Papertrail is proud to announce that we have been certified against the requirements of ISO...

About ISO 9001:2015 ISO established ISO 9001:2015 for *quality management systems, it comprises a...

Talk of ‘big data’ is all the rage in the wind industry. The ability to crunch massive amounts...

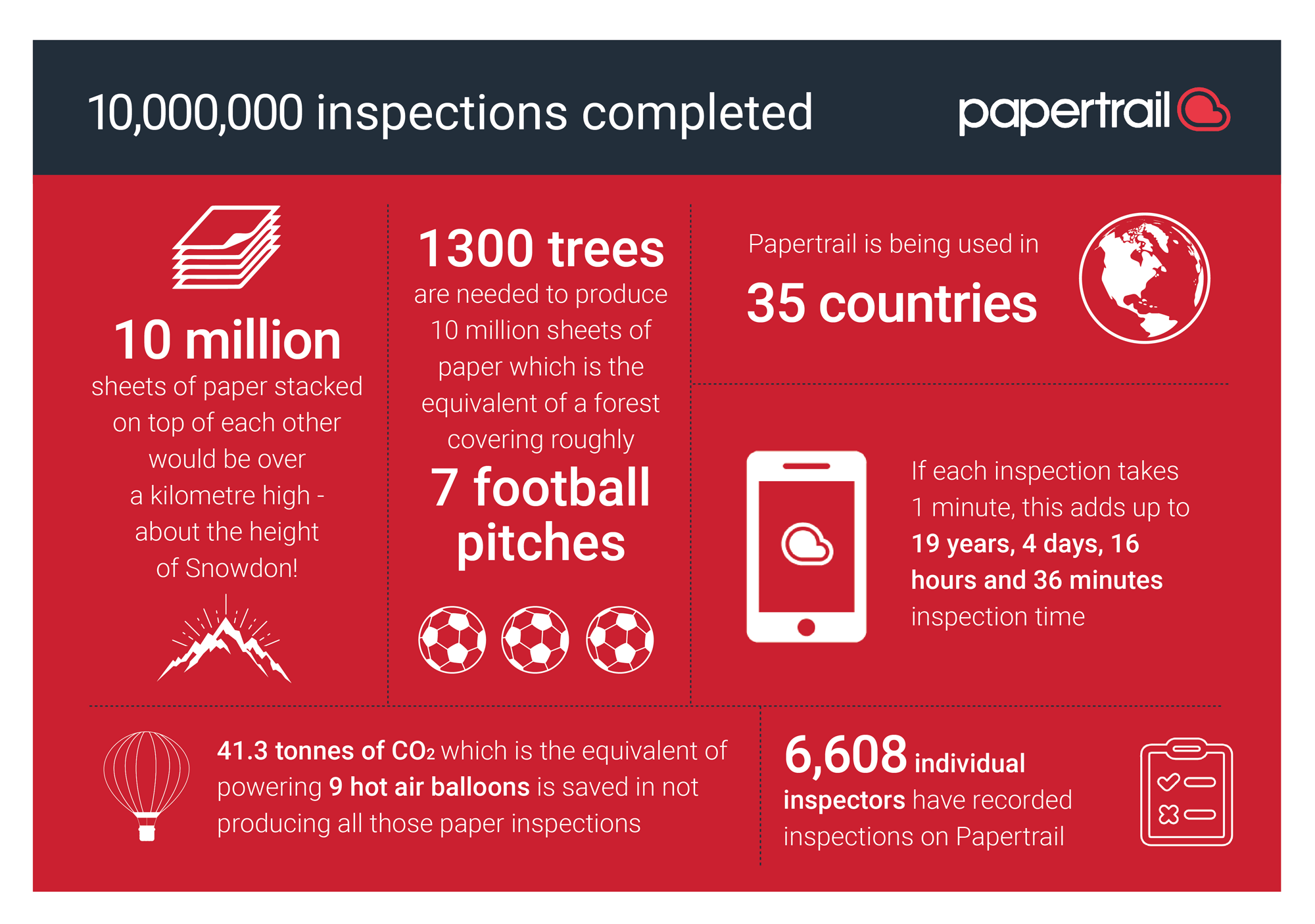

Today at Papertrail we are excited to announce that the platform has reached a total of 10 million...

Despite economic headwinds facing the UK oil and gas sector, safety is at the heart of operational...

We love getting feedback on how Papertrail subscribers are benefiting from our software and, more...

We live in exciting times for the energy industry. A shift to clean power is taking hold around...

Free! Download the 5 steps to reviewing your management system